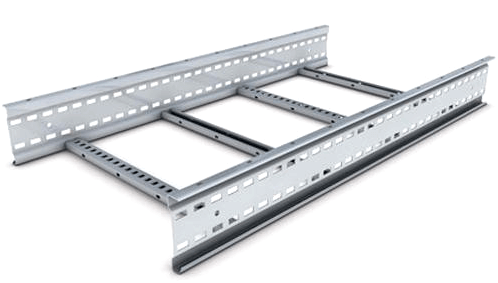

Ladder Cable Tray

Ladder Cable tray has two side rails connected by rungs. This type of cable tray is effective because the ladder rungs give you easy accessibility to the cables, from the top or bottom.

The rungs of the ladder cable trays provide convenient anchors for tying down the cables in the non-horizontal cable tray runs or where the positions of the cables must be maintained in the horizontal cable tray runs.

Product Specification

| Tray Width (W) | Runner Height (H) | Runner Collar (C) | Rung Size | Rungs Intervals | Rung Slot Size | Thickness(T) | Tray Length (L) | Finish |

| 150 mm or 1000 mm |

50 mm or 120 mm |

15 mm or 45 mm |

35×15 mm

40×20 mm 50×20 mm |

250 mm or 300 mm |

20×10 mm Width Spacing 10 mm/15 mm gap |

1.6 mm to 3.0 mm | 2500 mm or 3000 mm | Hot Dip Galvanized Powder Coated Enamel Painted |

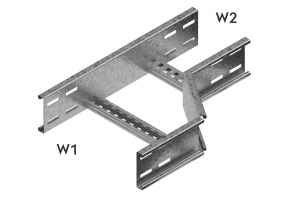

Our Accessories

Uses –

Ladder trays generally get used where there are larger bundles or heavier cables. The ladder cable tray has two side rails connected by cross members or rungs. The rungs provide convenient anchors for tying down the cables. A trough cable tray is a prefabricated structure consisting of a ventilated bottom with side rails. The ventilated trough cable tray supports cables better than the ladder type, but the additional support is not significant.

- Generally used in applications with intermediate to long support spans 12 to 30 feet.

- A ladder type cable tray is used for about 75 percent of the cable tray wiring system installations. It is the predominate cable tray type due to its many desirable features:

- A ladder cable tray without covers permits the maximum free flow of air across the cables. This allows the heat produced in the cable’s conductors to effectively dissipate. Under such conditions, the conductor insulation in the cables of a properly designed cable tray wiring system will not exceed its maximum operating temperature. The cables will not prematurely age due to excessive operating temperatures.

Other Uses –

- The rungs of the ladder cable trays provide convenient anchors for tying down the cables in the non-horizontal cable tray runs or where the positions of the cables must be maintained in the horizontal cable tray runs. This capability is a must for single conductor cable installations. Under fault conditions (short circuit), the magnetic forces produced by the fault current will force the single conductor cables from the cable tray if they are not securely anchored to the cable tray.

- Cables may exit or enter the ladder cable trays through the top or the bottom of the cable tray. Where the cables enter or exit the conduit, the conduit to cable tray clamps may be installed upright or inverted to terminate conduits on the top or bottom of the cable tray side rail.

- Moisture can’t accumulate in ladder cable trays.